SC Beverage makes use of extensive draft beer systems to deliver the highest quality and most flavorful beer products to our clients far and wide. Today, we are going to highlight our draft beer system and talk about how our dispensing system is used to deliver great beer to restaurants and facilities.

Below, we’ll talk about how the draft beer system works. If you are interested in learning more about the best beer equipment in Los Angeles, or if you want to learn more about what we do, follow us for important updates and check out how you can get more involved!

The Tanks

The first part of the draft beer system is the tanks. They can either be CO2 or a mix of CO2 and nitrogen, which are pressurized gas systems. This is the system that will push your beer into the faucet through the keg. Otherwise, there would be nothing to get the beer out other than gravity. This is what lets you pour your tap on demand any time you want!

The Regulators

The next step to completing your beer equipment in Los Angeles is to install a primary regulator. This regulator is what keeps the gases inside your tanks balanced so that they don’t contain too much pressure. If the regulators aren’t properly adjusted, then they will cause your beer to come out too foamy. Nobody wants to drink beer that is all foam and no substance!

Most regulators can control both high and low pressure, so you can quickly fix and readjust any issues with the pressure.

Then there is the secondary regulator. This regulator is what helps each keg dispense beer at exactly the right pressure. This is a great attachment to have alongside the primary regulator as it can control each individual keg, while the primary regulator controls the pressures overall. They go hand in hand, and they can save you some space, too!

Gas Blender

This important device helps you to dispense several different types of beers at once. If you love offering your customers a variety of beers and brews, you’ll definitely want a gas blender. This is what makes it possible to dispense drinks that have different gas requirements, such as just CO2 or a CO2/Nitrogen blend. This is a nice break from having to maintain different gas tanks all at once.

Air Lines

Every draft beer system has air lines, but what do the different colors mean? You typically will have a green air-line and a purple air-line. They are made of vinyl and they get your gas from the tank to the other parts of the system. They can attach to the regulator with a clamp to deliver directly into your system.

While they are often green and purple, many companies will make them red to distinguish between air and beer.

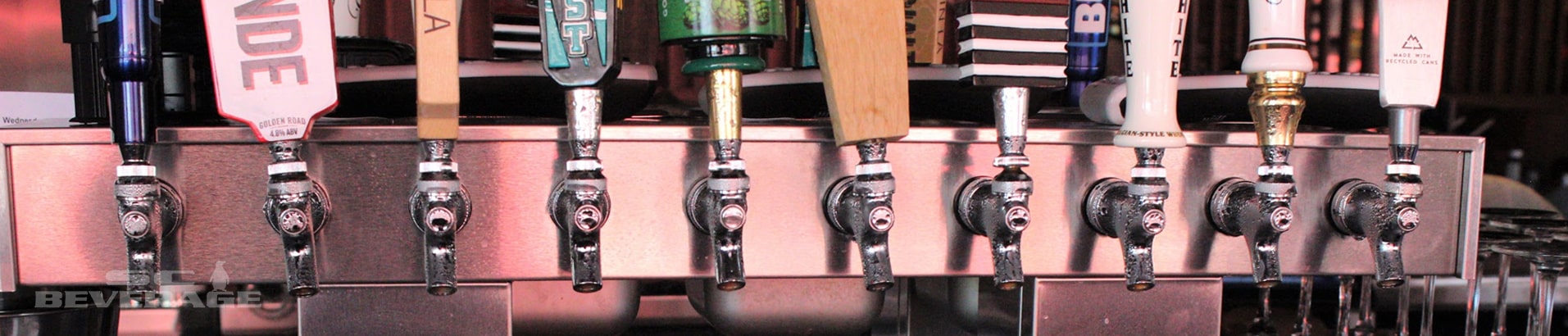

Faucets and Tap Handles

Now comes the fun part! Your draft beer faucets and tap handles are the systems that you use to directly dispense the beer. This is the most fun part of the whole system, as you get the satisfaction of pulling the tap and having that pressurized beer pour directly into a fresh pint glass.

Also keep in mind that there is a drip tray to catch any spills, as well as some extra features and components of your beer system that can be invested in to prevent extra cleanup chores.

Beer Equipment in Los Angeles

Our SC Beverage professionals are passionate about the ways we dispense beer. Using our beer equipment in Los Angeles, we can provide restaurants and clients with the ability to deliver a fully functional array of draft beers to their customers. If you are interested in building a draft beer system for your own business, you can contact us online or give us a call at (562) 463-8918.